Contact Us

TEL+86-411-62775690

FAX+86-411-62775691

MOBILE+86-13842676180

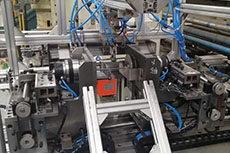

Our company is able to accomplish the whole project from design,produce,assembly,adjustment and commission through to project launch. Following on from this with on and off site maintenance along with programmed services our industrial engineering service offers the best of the combined proces.

Construct machinery and ancillary automation in a bespoke manner.

This allows us to fulfill the customers needs in this competitive market place.

1. Manually place the workpiece tray into the loading position on the right side, and the robot grabs one workpiece in sequence and moves it to the projection detection (TM-X5000) device;

2. Projection detects the specified size of the workpiece, determines OK or NG, and notifies the robot;

3. The robot grabs the OK parts and puts them into the finished product tray on the left, and puts the NG parts into the NG product tray in the middle;

4. This equipment is suitable for 35 varieties of workpieces.

1. Put the ejector rods into the silo in batches, and the silo lifts up and down with a washboard to automatically separate the rods to the designated position;

2. The handling device moves the rod step by step to the detection and pressing position;

3. At the detection station, the cylinder drives the detection points (3 places) to contact the rod, and at the same time the servo drive rod rotates. After one rotation, it flips back to the highest detected point (the highest point among the 3 points);

3. The servo drives the straightening block down, and performs straightening according to the high point error recorded in the test and the distance corresponding to the pressing error;

4. Repeat testing and straightening by pressing down until the test is qualified. If it is tested more than 5 times, it will be classified as NG;

5. The handling device moves the adjusted rod to the removal station, and the cylinder lifts and lowers to push the NG products into the NG product box.

1. Spring with outer diameter φ20~φ35 and length 30~200mm is pushed into the conveyor belt after manual sand removal;

2. A spring separation mechanism is installed from the spring to the end of the conveyor belt, and the separated single spring is pushed into the rotating rod;

3. The rotating rod raises the spring, and the servo press presses down to the preset height and then returns;

3. The rotating rod is rotated flat, and the mechanical gripper moves the pressed spring to the stepping V-groove transmission device;

4. The V-groove transmits the first position, and the servo plus cylinder combination drives the high-precision displacement sensor to detect the length of the spring and record OK and NG;

5. The V groove transmits the second position. If the spring is NG, the cylinder will push it into the NG product box. If OK, it will not move;

6. The V groove transmits the third position, and the spring of the cylinder OK pushes it into the OK product box.

To achieve the function:

Grab the angular pipe with the robot, set it on the feeder, send it to the press machine by the related equipment and press it.

turn the square pipe back and rotate it and press it on the other side.

To achieve the function:

7 parts are automatically supplied,assembled,and work in collaboration with robot

To achieve the function:

It is to machine a 6-axis of 500 mm to 700 mm in length into a chamfer on both ends and a groove with a width of 5 mm and a depth of 3 mm.